-

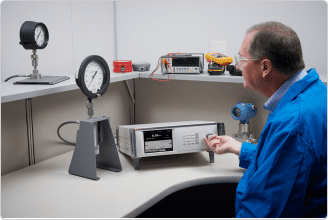

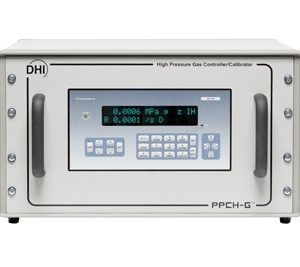

Widest workload coverage in an automated high-pressure controller

The 8270A and 8370A are automated pneumatic high-pressure controllers that calibrate a wide workload of pressure sensors, covering twice the pressure ranges at twice the speed of other high-pressure controllers. Two models let you balance price and performance:- The 8270A measures and controls pressures from vacuum to 44 MPa (6400 psi). It can be configured with ranges as low as 100 kPa (15 psi).

- The 8370A measures and controls pressures from atmosphere to 107 MPa (15 500 psi). It can be configured with ranges as low as 700 kPa (100 psi).

Fluke Calibration’s unique control technology enables you to use these calibrators at low or high pressures, all in the same instrument. Control precision is 0.002% of active range.Expand workload coverage to both gas and liquid filled devices by using the optional Contamination Prevention System (CPS).

100:1 control turndown

Flexible configuration options

| Good: PM200 Pressure Measurement Modules | Better: PM500 Pressure Measurement Modules | Best: PM600 Measurement Modules |

|---|---|---|

|

|

|

Modern replacements for hydraulic deadweight testers and comparators

Safety: the number one priority

Calibrate oil or gas devices without risk of contamination

Easiest to use high-pressure standards available

Flexibility to handle a wide variety of applications and workloads

An affordable solution that can grow as your requirements do

Ideal for characterization or calibration in production processes

Robust design provides unsurpassed control performance

Modularity makes maintenance a snap

Control speed meets the demands of a manufacturing environment

Support for remote communication and automation

Clean operation to 100 MPa (15 000 psi)

Automate with COMPASS® software

Support and services when you need them

Get peace of mind and uptime with a Gold CarePlan

Training options help you to get the most from your investment

General specifications |

|

| Mains | |

| Power requirements | 100 V ac to 240 V ac, 47 Hz to 63 Hz |

| Fuse | T3.15 A 250 V ac |

| Max power consumption | 100 W |

| Environment | |

| Operating ambient temperature range | 15 °C to 35 °C |

| Storage temperature | -20 °C to 70 °C |

| Relative humidity | Operating: <80 % to 30 °C, <70 % to 40 °C |

| Storage: <95 %, non-condensing. A power stabilization period of four days may be required after extended storage at high temperature and humidity. | |

| Vibration | MIL-T-28800E |

| Altitude (operation) | <3000 m |

| Warm up time | 15 minutes after power up or module installation, when items previously stored within Operating Ambient Temperature Range. |

| Compliance | |

| Ingress protection | IEC 60529:IP20 |

| Safety | IEC 61010-1, Installation Category II, Pollution degree 2 |

| Weight and Dimensions | |

| Weight (Chassis only) | 13 kg (28.5 lbs) / 15 kg (35.25 lbs) |

| Dimensions | Height: 147 mm (5.78 in) |

| Width: 452 mm (17.79 in) | |

| Depth 488 mm (19.2 in) | |

| Rack mount dimensions | 3U-19 inch rack |

| Electromagnetic Compatibility (EMC) | |

| IEC 61326-1 (Controlled EM environment | IEC 61326-2-1; CIPR 11: Group 1, Class A Group 1 equipent has intentionally generated and/or uses conductivity coupled radio-frequency energy which is necessary for the internal functioning of the equipment itself. Class A equipment is equipment suitable for use in all establishments other than domestic and those directly connected to a low voltage power supply network which supplies buildings used for domestic purposes. Emissions which exceed the levels required by CISPR 11 can occur when the equipment is connected to a test object. The equipent may not meet the immunity requirements of 61326-1 when test leads and/or test probes are connected. |

| USA (FCC) | 47 CFR 15 subpart B, this product is considered an exempt device per clause 15.103. |

| Korea (KCC) | Class A Equipment (Industrial Broadcasting & Communication Equipment) This product meets requirements for industrial (Class A) electromagnetic wave equipment and the seller or user should take notice of it. This equipment is intended for use in business environments and not to be used in homes. |

| Communication Interfaces | |

| Primary Remote Interfaces | IEEE, Ethernet, RS-232, USB |

| System Connection | Supports interconnection of 2 or 3 systems |

| Switch Test Connection | Standard BNC Jack: Nominal 24 V dc isolated drive Maximum 30 V dc w.r.t.chassis ground |

| Aux Drivers | 4 external Solenoid Drivers 24 V dc Drive (Maximum drive 6 W continuous per channel |

| Operating characteristics | ||||||||||||||||||||||||||||||

| Control specifications | ||||||||||||||||||||||||||||||

| 95 % of setponts are within specification limits for stated conditions as calculated by mean plus 1.67 standard deviations of test data. | ||||||||||||||||||||||||||||||

| Control Precision (Dynamic Mode) | 0.002% Range Span or 0.01 kPa (whichever is greater) | |||||||||||||||||||||||||||||

| Control Turndown | 100:1 (typical)

To meet the control specifications, supply pressure should not be greater than 100 times the range of the measurement module. Control turndown is defined as the relationship between the provided supply pressure and the appropriate supply pressure for the range |

|||||||||||||||||||||||||||||

| Low Control Point | 1 kPa (0.15 psi) absolute (8270A only) 7 kPa (1.0 psi) gauge (8370A, 8270A without vacuum pump) |

|||||||||||||||||||||||||||||

| Settling Time | Settling time is the time required to be within 0.005% of setpoint for 10 % steps into volumes up to 50 cm3 for all pressures >7 kPa absolute (8270A) or 7 kPa gauge (8370A). Settling time may be affected by multiple variables, including temperature effects, component flow rates, leaks, and overall volume configurations.

|

|||||||||||||||||||||||||||||

| Overshoot (Dynamic A) | 0.08% Full Scale or 2 kPa (whichever is greater) | |||||||||||||||||||||||||||||

| Overshoot (Dynamic B) | 0.008% Full Scale or 2 kPa (whichever is greater) | |||||||||||||||||||||||||||||

| Pressure Limits | ||||||||||||||||||||||||||||||

| Supply Port (8270A/8370A) | Maximum 48 MPa (7 000 psi) gauge / 110 MPa (16 000 psi) gauge Minimum 2 MPa (300 psi) gauge for 8270A and 8370A |

|||||||||||||||||||||||||||||

| Test Port (8270A/8370A) | 44 MPa (6 400 psi) gauge / 107 MPa (15 500 psi) gauge | |||||||||||||||||||||||||||||

| Reference Port | 150 kPa (22 psi) absolute | |||||||||||||||||||||||||||||

| Vent Port | 150 kPa (22 psi) absolute | |||||||||||||||||||||||||||||

| Relief Valves/Rupture Disk | ||||||||||||||||||||||||||||||

| 8270A Chassis Supply port relief valve is set to 52 MPa (7 500 psi)

8370A Chassis Supply has a rupture disk installed which is designed to burst at Modules with full scales ≤ 44 MPa include pressure relief valves |

||||||||||||||||||||||||||||||

| Supply Gas Type | ||||||||||||||||||||||||||||||

| Clean Dry Nitrogen, Helium, Argon, or Air - Industrial Grade Nitrogen, 99.5%+ | ||||||||||||||||||||||||||||||

| Vacuum Supply | ||||||||||||||||||||||||||||||

| >50 liters per minute capacity with Auto Vent feature

System will exhaust gas through the vacuum system when controlling down in pressure. Appropriate protections are necessary. |

||||||||||||||||||||||||||||||

| Accessory | Description |

|---|---|

| PM200 Pressure Measurement Modules | For 2271A Industrial Pressure Calibrator, and 6270A, 8270A and 8370APressure Controller/Calibrators |

| PM500 Pressure Measurement Modules | For 2271A Industrial Pressure Calibrator and 6270A, 8270A and 8370A Pressure Controller / Calibrators |

| PM600 Pressure Measurement Modules | For 6270A, 8270A and 8370A Pressure Controller/Calibrators |

| CPS-100M | High-Pressure Contamination Prevention System, Std Port/Adptrs |

| CPS-40M-HC40 | Pressure Measurement Module Calibration Kit |

| SPLT-40M | Self-Purging Liquid Trap |

| PK-8270-BSP | Lines and Fittings Kit, 8270A BSP |

| PK-8270-NPT | Lines and Fittings Kit, 8270A NPT |

| PK-8270-SAE | Lines and Fittings Kit, 8270A 7/16-20 |

| PK-8370-100M | Lines and Fittings Kit, 837X |

| TST-100M | High-Pressure Test Station, Std Port/Adaptors |

| TST-40M-HC40 | Test Station, Std Port/Adaptors |

| GBK-110M | Gas Booster Kit, 152:1, 110 MPA (16 000 PSI) |

| GBK-50M | Gas Booster Kit, 75:1, 50 MPA (7300 PSI) |

| VA-PPC/MPC-REF-110 | Vacuum Pump Package, 110 V |

| VA-PPC/MPC-REF-220 | Vacuum Pump Package, 220 V AC |

| CASE-PMM | Shipping Case, 3 PMM Modules |

| CASE-XX70 | Reusable Transit Case for XX70 |

| KIT-PMM-CAL-100M | High-Pressure Measurement Module Calibration Kit |

| KIT-PMM-CAL-40M | Pressure Measurement Module Calibration Kit |

| CDG-REF-1TORR |

Capacitance Diaphragm Gauge for zeroing of Absolute Mode PM500 Modules

|

| PK-PMM-ZERO | Interconnection Kit for zeroing of Absolute Mode PM500 Modules |

| RMK-XX70 | Rack mount Kit, 19 In Width, 3U |

| PK-VLV-ABORT-100M | Kit, High-Pressure Abort Valve |

| PK-VLV-ISO-100M | Kit, High-Pressure Isolation Valve |

| PK-VLV-ISO-40M | Kit, Pressure Isolation Valve |

| 6270-SYS-CBL | 6270A System Cable Kit |

| KIT-EMM300 | Electrical Measurement Module with Docking Station |

| DS70-KIT-EMM | Electrical Measurement Module Docking Station |

| EMM300 | Electrical Measurement Module |

| SK-8270-SERVICE | Seals Kit, 8270 Service |

| SK-8370-SERVICE | Seals Kit, 8370 Service |

Application Notes |

|---|

| Guide to determining pressure measurement uncertainty for PM200, PM500 and PM600 Pressure Measurement Modules |

| Performing high-pressure calibration |

Data Sheets |

|---|

| 8270A and 8370A Modular Pressure Controllers/Calibrators |

Request a quote - Shop