The advantages of an Automated Mass Handler

Since some time, Minerva’s laboratory is in possession of a number of deadweight testers which are equipped with Automated Mass Handlers. What exactly is an Automated Mass Handler, how does it work and how does it benefit Minerva’s customers? Let’s ask Jim de Rouw, senior calibration technician at Minerva.

How does an Automated Mass Handler work?

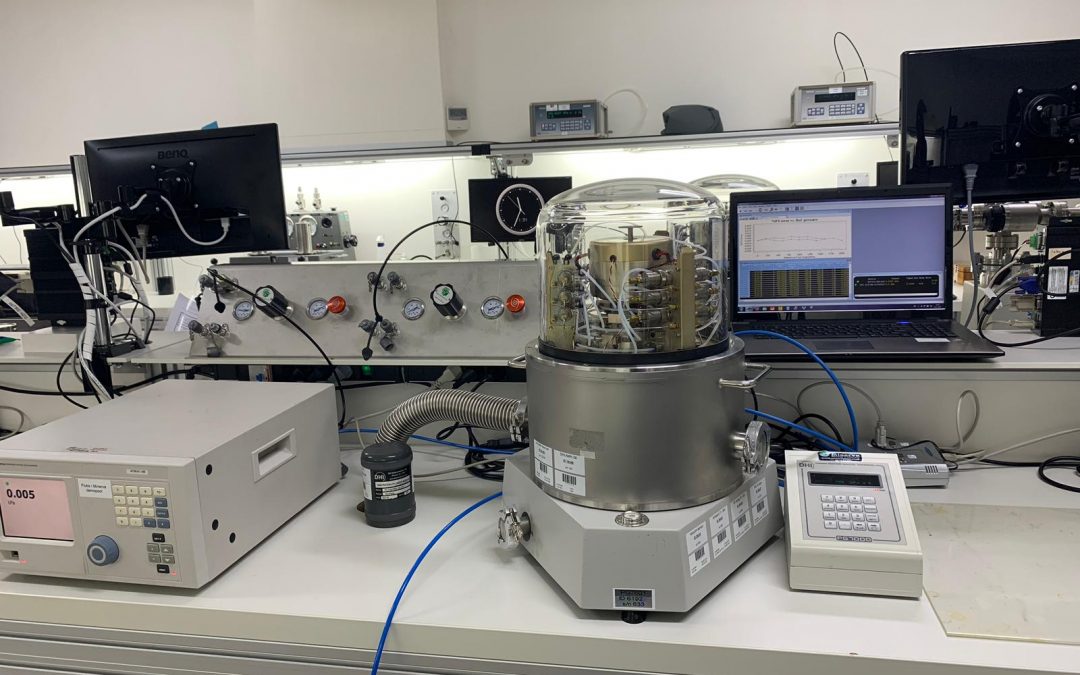

Jim: “The Automated Mass Handler (AMH) is an extension to a deadweight tester. The total setup consists of a deadweight tester, an automatic pressure controller (Pressure Controller (PC) and an Automated Mass Handler. The deadweight tester is made up out of a platform, a piston/cylinder and a mass set. The mass set is placed on the piston and subsequently pressure is generated which causes the piston and mass set to float. The pressure then corresponds to the mass x gravity on the effective surface of the piston. In the platform, all measurement data of the plunger is recorded with the specific meteorological values of measurement. The display of the platform indicates which mass pieces are required to be placed on the plunger to create a certain pressure. Adding and removing mass pieces is a manual process, necessary to achieve the accuracy specifications that can only be achieved with a deadweight tester.

An Automated Mass Handler is much like a robot that places the mass pieces on the plunger, effectively rendering all manual actions redundant. The electronics of the deadweight tester guide the pressure controller in such a way that the pressure inside the system coincides with the pressure that is put on the piston and the added mass pieces.

The entire setup of the AMH in combination with the pressure controller and deadweight tester operates completely autonomous. As a result, Minerva is capable of carrying out fully automated pressure calibrations that are extremely accurate.

At Minerva, we currently have three Automated Mass Handlers which can be used to service our customers:

- Two AMH’s that are gas operated (N2) with a maximum range of 70 bar (gauge and absolute);

- One AMH using oil, up to 2000 bar.

What is required for the set up to work correctly?

Jim: “For the entire set up to work effectively both the accuracy specifications and measuring points as requested by the customer are required. This data will be registered into the calibration software we use, called Compass for Pressure”.

What advantages does the Automated Mass Handler offer the customer?

“Using an Automated Mass Handler will result in the following advantages to the customer:

- High-end equipment will also be calibrated in a very accurate manner, upholding high standards;

- High-standard, accurate calibrations are carried out fully automated;

- Human uncertainties are taken out of the equation. The result is a 100% certainty of the accuracy of any conducted calibration.

Finally, the duration of the calibration process is decreased, resulting in lower turn around times for our customers.

januari 29, 2019