Why a Fluke calibration bath?

A calibration bath is an ideal temperature source for temperature calibration. Each year Fluke Calibration sells more calibration baths for temperature calibration than any other bath maker in the world.

Metrologists are, by nature, extremely concerned about instrument performance. In this market you don’t reach this level of acceptance simply through aggressive salesmanship. Instruments have to deliver a measurable difference.

One difference is that the Fluke calibration baths are each designed specifically for metrology. They are not adaptations of equipment designed for biology or chemistry labs, and that’s why their performance meets the requirements of a calibration lab. There’s nothing mysterious or magical about Fluke baths. We don’t expect you to simply believe us. We want you to be skeptical so we can prove to you how good our baths are. We’ll tell you how a Fluke Calibration bath is made and why it performs better than any other bath in the world.

Range of Fluke calibration baths

Fluke offers a wide range of calibration baths

Five types of baths are available: standard, compact, deep-well compact, resistor and custom baths. The wide range of baths means you’ll absolutely find one to meet your application and budget, whether you’re working in a primary standards laboratory or an industrial workshop. Standard baths, a favorite with National Metrology Institutes (NMI), range in temperature from –80 °C to 550 °C with typical stability and uniformity as good as 2-3 milli-Kelvin (some as good as 0.7 milli-Kelvin). Fluke Calibration standard baths have larger well openings than other baths. This makes them an excellent choice for sensor manufacturers and other applications that test large batches of sensors or special probes of unusual size and shape.

If you don’t need the stability performance of a standard bath, the Fluke Calibration compact baths are the perfect alternative. Packaged in a smaller footprint, the compact baths range in temperature from –80 °C to 300 °C, are stable to within 5-10 milli-Kelvin and have faster heat/cool times than standard baths. The deep-well compact versions offer a full 457 mm (18 in) of immersion depth with an optional fluid-level adaptor for calibration of total and partial immersion liquid-in-glass thermometers.

For maintaining your standard resistors for electrical or temperature calibration work, a Fluke Calibration resistor bath will provide unmatched stability and uniformity, as good as 0.7 milli-Kelvin, and large working volumes, up to 67 x 56 x 33 cm. If your needs aren’t met by our standard sizes and temperature ranges, we can build a reliable, high quality custom bath for you. For example, we have built baths with significant tank changes (taller, wider or deeper), custom temperature ranges, different height or shape, and faster heat/ cool rates. We have built baths that require windows or custom dimensions to accommodate test fixtures. No other manufacturer supplies custom baths to their customers; but we do.

Controllers

The first step in evaluating a bath is to look at its temperature controller. We designed our own proprietary control technology to deliver stability to ±0.0001 °C with features that make your work go more quickly. Flukes hybrid analog and microprocessor design is unique. Set-point resolution is 0.01 °C (0.002 °C on some models), and our “Super-Tweak” resolution mode shifts the controller display so you can adjust the bath set-point to the fifth decimal place. Although thermal noise in the bath is measured at four decimal places, the “Super-Tweak” function still gets you closer to an absolute temperature than any other controller. If you need a bath set at exactly 25.000 °C, a Fluke Calibration bath gets you there with less effort than any other bath. Eight of your most frequently used set-point temperatures are stored for quick recall and faster bath setup. Temperature can be easily switched between Celsius and Fahrenheit. Safety cutout temperatures are also set on the LED display.

Fluke Calibration baths are each fitted with a high-stability PRT or thermistor as the control sensor. Our controller uses special noise-rejection techniques to allow us to measure the very tiny resistance changes required for this level of bath stability. In this design we use ac bridges to reduce thermal EMFs. Custom, high-precision, low-coefficient resistors contribute to short- and long-term stability of the temperature setting, and advanced filtering techniques force out line noise along with stray EMIs and RFIs. A proportional, integrating control function directs power to the bath heaters. Factory tuning eliminates most overshoot and allows the bath to achieve maximum stability within 10 to 15 minutes after reaching the set temperature.

Automation

The next thing to evaluate is automation. Calibration baths take time to adjust from one set point temperature to another. You can minimize the changeover time with automation. You can also streamline the process, reduce operator time, and cut down your turnaround time. Fluke Calibration offers a number of automation options. You can select from an RS-232 interface or IEEE-488. The RS-232 packages come complete with Interface-it software so you can immediately start controlling your bath from a PC without any programming skills.

Even refrigerated baths can be automated. Like many other baths, Fluke Calibration’s entry-level benchtop bath series uses a simple on/off function to control refrigeration power. However, Flukes higher performance baths use a heating/cooling equilibrium design that’s unique in the industry. A manual valve adjusts the cooling power to properly balance the refrigeration against the active control of the resistance heaters. Fluke Calibration’s bath interface packages include automated valves to make these adjustments automatically by your PC.

Heat port technology

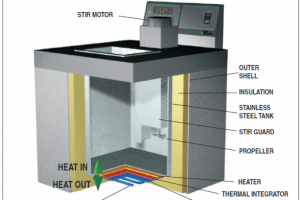

The tank bottom design for Fluke Calibration standard baths features a heat port, minimizing gradients and maximizing uniformity and stability.

A major factor in Fluke Calibration’s standard bath performance is our heat port technology. Some bath designs place separate heating and cooling coils directly in the bath reservoir. In this scheme, heat enters and exits the bath at two different physical locations.

Fluke Calibration improves bath uniformity and stability by reducing the heat paths from two to one. The cooling coil and the heater of a standard bath are sandwiched to the outside of the bath’s stainless steel tank. The tank bottom becomes the heat port with most of the heat entering and exiting the bath through a single location. Other heat leaks are minimized by providing welldesigned insulation around the tank.

Mixing

For mixing the bath fluid, Fluke Calibration uses a carefully balanced stirring mechanism. The number of propellers and the pitch of the blades are adjusted to thoroughly mix the bath medium and eliminate both horizontal and vertical radients. Fluke doesn't use circulating pumps, because the tubular inlet and outlet design cause thermal-flow patterns in the bath that create unnecessary gradients. Flukes mixing scheme and the size and shape of the tanks all combine to deliver great performance.

Maintenance

Fluke Calibration baths are easy to maintain because our stir motors last longer; there are no pumps to unclog or repair. Flukes bath tanks are easier to clean

There’s a reason we sell more temperature calibration baths than anybody else. You’ll never have to apologize to your boss for having bought one. Fluke Calibration manufactures its own stainless steel tanks to ensure world class performance and reliability.

Find Fluke calibration baths in our shop

juillet 25, 2017