How customer demands changed Minerva’s Quality Standards

Over the last 30 years we have developed a thorough quality system focused on responding to customer feedback. Thanks to a clear workflow and weighting system we register, rank and act on complaints. This has led to an balanced quality system, anchoring our ISO accreditation and ensuring the continuous improvement of all our products and services since 1988. Carel Adolfse, Technical Director of Minerva, explains the origin and set up of this quality system and the preparation for the future ISO/IEC 17025 standards.

Customers asking for traceability and measurement uncertainty

Already in 1987 our company Minerva was selling high end metrological equipment for more than 20 years. Our demanding customers started asking questions about the quality of measurements and performance assurance of supplied equipment. We anticipated on those questions by setting up a dedicated area where we compared customer devices against a Minerva reference standard.

But customers became more and more aware of metrological concepts, like traceability and measurement uncertainty, and started to ask Minerva to take steps to assure the quality of these measurement comparisons.

You can say that this was the driver for Minerva to take her first preventive action by initiating a project to obtain an accreditation by the predecessor of the RvA (Dutch Council for Accreditation).

Carel Adolfse was asked by the Minerva management at that time to lead this project. Carel: "I was kind of skeptic about the benefits it could bring our company. With today's knowledge I have to admit I was totally wrong and I can say that this was one of those decisions which changed the evolution of Minerva (and in such my life too)."

The start of our ISO/IEC 17025 quality system

This all changed in 1999 when the first edition of ISO/IEC 17025 was published and our accreditation needed to comply against this standard. Quality as a concept now was much more embedded in the standard and our way of thinking as a small company needed a major adjustment.

In the 11 years of accredited experience and me growing older, I had a much better idea of what was needed and completely re-wrote our quality system according to the ISO structure. In contradiction of our initial system, now our quality system was designed with practical use in mind.

One major improvement in our system was (and still is) continuous improvement driven by complaints, preventive and corrective actions."

Complaints: Our quality system implementation today

Having complaints looks like a contradiction to quality but it's definitely not! The challenge for us, and I guess for all of you, is how we define of what we consider to be a complaint. It is probably true that when you do not receive complaints, your definition of complaints is wrong! At Minerva we distinguish two different types of complaints:

- internal complaints

These are complaints initiated by Minerva staff prior to finishing a project. For example: we execute an internal (preventive) action which is only noticeable inside Minerva, the customer will never know something has happened. We believe that it is important to also record and formally process these type of complaints. - external complaints

These are complaints initiated by others outside Minerva staff (like customers). Obviously a complaint of a service noticed by the customer has more exposure and in that way is more serious. However, the seriousness of the complaint itself can be the same as an internal one.

Started as a simple complaint registration in our database, the complaint registry module has evolved into a system with pre-defined work flow and means to measure how serious a complaint is. We have defined a workflow and a weighting for complaints.

Complaint workflow

- status open / pending / processed

- cause description of cause analysis

- impact description of the impact of the complaint

- corrective action description of corrective actions to be undertaken

- effectiveness proof of corrective action

- due date when the action needs to be completed

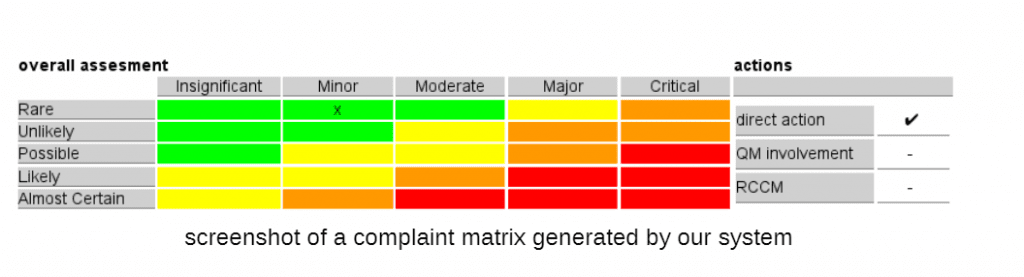

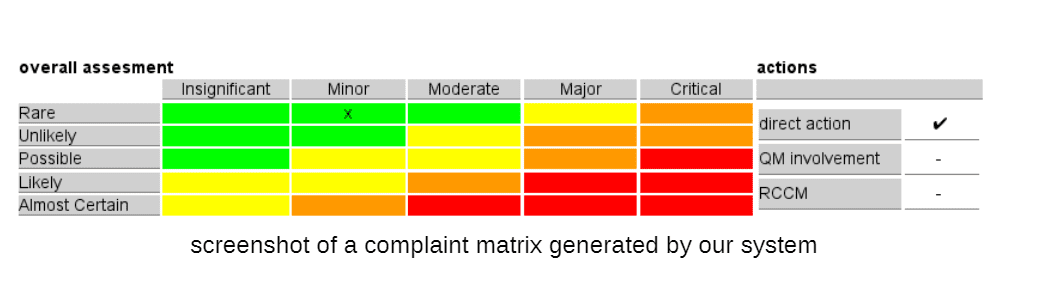

Weighting complaints

- severity 5 possible stages

- likelihood 5 possible stages

Based on the weight (matrix of severity and likelihood), the subsequent action is calculated by our registry system:

- direct action

Follow the workflow and close the complaint. The complaint will be reviewed in the next management review and if the type of complaint has occurred more often than predicted, additional actions can be initiated. - QM involvement

Follow the workflow and inform the quality manager. Based on his decision the complaint may be closed OR additional actions need to be undertaken as described in our Root Cause Counter Measure (RCCM) procedure. - RCCM

No direct action, immediately inform the quality manager, he will initiate RCCM procedure and determines what corrective actions are needed to assure this complaint will never happen again.

The source of complaints

In order to smoothen the corrective action process, we identified 5 areas which might have caused the complaint to arise from:

- facility

- staff

- organization

- process

- product

Complaints can be filtered on root source which makes a potential overall defect much better detectable.

The future of ISO/IEC 17025

Most of you working with ISO/IEC17025 should be aware of the upcoming revision (projected to be launched in December 2017). The new ISO/IEC 17025 focuses on risk assessment.

At Minerva, we are confident that our complaint processing procedure already is compliant with this risk assessment approach and we hope this article increases the awareness of the importance of complaints as a driver for continuous improvement.

ABOUT MINERVA METROLOGY AND CALIBRATION

Minerva Metrology and Calibration is focused on providing premium calibration services and products, ensuring carefree traceability for our customers.

For recalibration and service of pressure calibration equipment we have extremely knowledgeable staff and a very well equipped, innovative and ISO/IEC 17025 accredited laboratory. Within the BeNeLux we also supply pressure, mass flow, electrical and temperature calibration equipment as well as calibration software. Worldwide we sell our own product line of Minerva calibration equipment.

Would you like to know more about our quality system of ISO/IEC 17025 standards? Feel free to contact Carel Adolfse via adolfse@minerva-calibration.com

März 16, 2017